Skirting

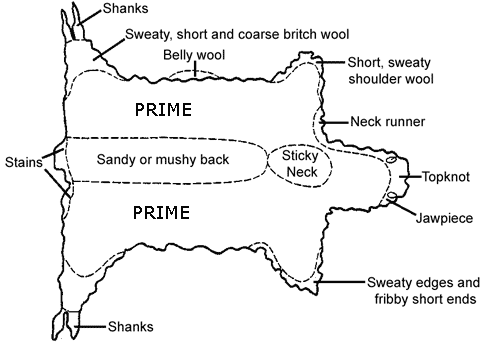

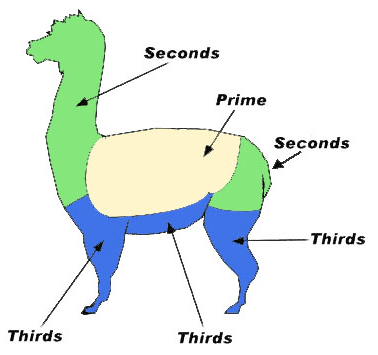

Fleece preparation starts with skirting (which is the removal of any detrimental parts) is necessary for producing high quality wool products. Being brutal in fibre skirting ensures you will get the highest quality products from your raw fleece, along with maximizing your fibre processing investment dollars. Avoid seconds cuts while shearing, and if they do sneak in, be sure to remove them as you skirt your fleece. Belly, neck and hind (britch) wool should be removed. These are normally heavily soiled and matted, and will not process in the milling machinery.

Organic material in fleeces decreases their value. Examples are heavy tags (manure and sweat locks), seeds, thistles, straw and burrs. Removal of these items is required before shipping for processing. Please discard all the wool containing any of the above mentioned examples. Excess water (the result of shearing damp or wet animals) not only reduces yield, but may permanently damage the wool from mold or mildew. Remove sections that contain scurf. Dispose of any fleece with signs of containing moths.

Reduce foreign material in fleeces by:

- Shearing only dry animals.

- Remove all belly, britch, and neck wool.

- Separating heavy tags into separate bags.

- Use of "clean" bedding free of excess seeds or chaff.

- Using hay racks and grain troughs which do not let fleeces get contaminated.

- Checking pastures for burrs, thistles and other weeds and destroying them before they go to seed.

- Removing other sources of contamination like greasy machinery.

Processing

Expect between 40% and 60% weight loss from your raw wool weight to the finished weight. This loss in weight is from removal of dirt, dust, barnyard waste, and grease from the fiber.

Best results are obtained from fibre that is over 2" and under 10" for the staple length. The mill is not responsible for the health of the fibre sent in. Fibre should be strong and pass a strength test. If the fibre is found to not be suitable for a process, we will contact you and work with you and your fibre to the best of our ability. If our recommendations are ignored, we are not responsible for the final product.

If you don't want it in your final product, don't send it. Please contact us if there are any questions.